COVID-19 Update: ASI

The spread of COVID-19 has disrupted every aspect of our lives and things are changing quickly. The Director of the Ohio Department of Health (ODH) has issued a "Stay at Home" order in response to the Coronavirus (Covid-19). ASI qualifies as an Essential Business Operation and will continue full operations. We are following the important guidance from the CDC to safeguard the health and wellbeing of our customers, our team, their families, and will continue to monitor for updates.

We understand that this is a challenging time for many of our customers. You can be assured that our team is ready and able to assist you and your company in any way that we can.

Thank you for the continued support, and we look forward to working with you through these unprecedented and difficult times.

Metallurgical News

ARTICLE Managing Coreless Induction Furnace Slag Build-Up

By Rod Naro

Modern foundries must balance cutting melt costs and maintaining operational efficiency. Inexpensive scrap metal can lower costs but often lead to inefficient furnace operations and increased slag-related problems.

Properly using fluxes can alleviate these problems. It can also increase melting efficiency, save time and electricity, and improve foundry profitability. Redux EF40L has been shown to be effective in reducing slag viscosity and eliminating slag build-up in various types of furnaces and ladles.

Click here to view the article.

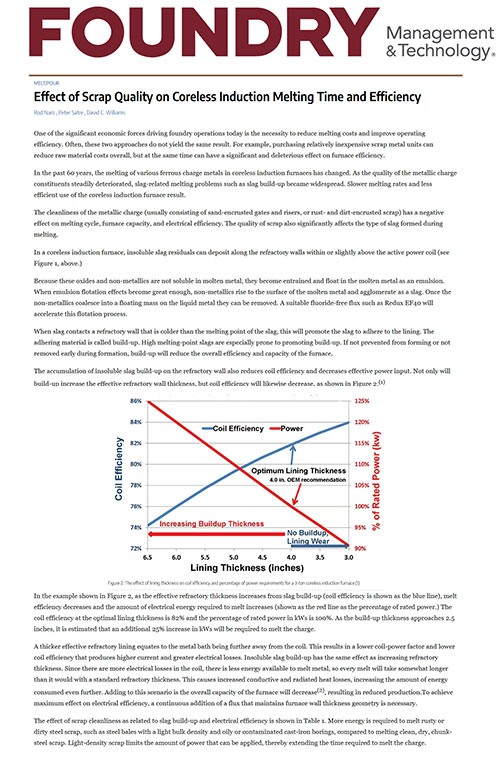

ARTICLE Effect of Scrap Quality on Coreless Induction Melting Time and Efficiency

By Rod Naro, Peter Satre, and D.C. Williams

One of the significant economic forces driving foundry operations today is the necessity to reduce melting costs and improve operating efficiency. Often, these two approaches do not yield the same result. For example, purchasing relatively inexpensive scrap metal units can reduce raw material costs overall, but at the same time can have a significant and deleterious effect on furnace efficiency.

In the past 60 years, the melting of various ferrous charge metals in coreless induction furnaces has changed. As the quality of the metallic charge constituents steadily deteriorated, slag-related melting problems such as slag build-up became widespread. Slower melting rates and less efficient use of the coreless induction furnace result.

Click here to view the article.

ARTICLE Global Impact of Redux Fluxes to Reduce Slag Build-Up

By Rod Naro and D.C. Williams

Newly engineerred fluxes can extend refractory life in coreless induction furnaces, prolong service life of pouring ladles, and significantly reduce slag and/or dross.

During the past 40 years, the melting methods andassociated molten metal-handling systems used by U.S.foundries have changed significantly. Further, the qualityof metallic scrap and other iron-unit feed stocks hassteadily deteriorated. The result: Increased slag generationand slag related melting problems have becomewidespread issues in recent years. A search of the foundrytechnical literature about slag control and build-up from the past 40 years finds only a handful of articles.

Click here to view the article.

Case Study #1 Internal Foundry A: REDUX EF40L Flux TRIAL

OBJECTIVE

Clean slag buildup from coreless induction furnace walls

TEST CONDITIONS

- Metal Grade - Grey Iron

- Item Name - Differential Housing & 3 Cylinder Engine Block

- Furnace Capacity - 7 Metric Tons

- Furnace Number - 1

- Heat No - 308

Trials were conducted at the furnace:

- Redux addition level - 0.05% of metal based on treated metal weight, i.e. 3.5 kg per heat of 7 metric tons.

- Half of the 3.5 kg of Redux was added with 50% of the charge, and the balance after melting started.

RESULTS & CONCLUSIONS

The furnace was mostly clean and free from buildup after just one Redux EF40L addition; a second and third addition of Redux appeared to remove all slag buildup.

Foundry A was very satisfied with the performance of Redux EF40L!

ARTICLE Elimination of Sub-Surface Pinhole Porosity Defects In Alloy Steels By Ferroselenium Additions

By Rod Naro and D.C. Williams

- Understanding humidity and resulting porosity

- Elimination of Sub-Surface Porosity in High Alloy Steels

- Case study shows effective solution for preventing subsurface porosity

Click here to view the article.

ARTICLE Economic Consequences of Insoluble Buildup on Coreless Melting Efficiency

By Rod Naro and D.C. Williams

- Improve Coreless Induction Melting Efficiency

- Reduce Melting Electrical Costs

- Eliminate Refractory Wall Slag Buildup

Click here to view the article.

ARTICLE Inexpensive Method to Produce Compacted Graphite Iron Without Costly Thermal Analysis

By Rod Naro and D.C. Williams

- Precise control of sulfur recovery for ductile iron & compacted graphite iron

- Amount of sulfur addition in magnesium-treated iron needed to obtain a critical nodular graphite/compacted graphite (NG/CG) ratio depends many factors

Click here to view the article.

ARTICLE Coreless Furnace Fluxing Benefits for Ferrous Foundries

By Rod Naro, Mark King, D.C. Williams and Lenny Basaj

- Fluxes for melting iron in induction furnaces to combat slag

- Preventing insoluble build-up deposition in coreless induction furnaces

Click here to view the article.

ARTICLE Mechanism and Reduction of Insoluble Slag or Dross for Cleaner Metal

By Rod Naro, Mark King, D.C. Williams and Lenny Basaj

- Increasing cell count in grey iron, especially for thin section castings

- Understanding the sulfur effect in treated ductile iron for a given magnesium content

- Why you should improve standard calcium bearing 75% ferrosilicon inoculation in cast irons

Click here to view the article.

ARTICLE Improved, High Performance Rare Earth-free Inoculants

By Rod Naro, Mark King, D.C. Williams and Lenny Basaj

To learn more about how Sphere-o-Dox saved a foundry an estimated $750,000 (annual), read this article in the issue of Foundry Magazine. This article is on page 19.

Click here to view the article.

NEW Technology and Products to Reduce Costs and Improve Quality & Efficiency

- Redux EF40L and EF40LP Electric Furnace Fluxes

- Fluoride-free fluxes for ladles, channel, coreless and pressure pour furnaces

- Sphere-o-Dox (U.S. Patent 6,281,988 B1) Inoculants

- Ultra-high performance inoculants

- Inocu-Bloc (U.S. Patent 6,281,988 B1) In-Mold Inoculation Systems

- Nodu-Bloc Low Silicon Nodulizers

- Resulf 30 (U.S. Patent 6,733,565 B1) CG Iron Additive

- Resulf 30IE (U.S. Patent 6,866,696 B1) Inoculant Enhancer

- Improves inoculation

- increases nodule count

- reduces chill

- "rejuvenate dead irons"

- works with any inoculant