Noticias Metalúrgicas

ARTÍCULO Managing Coreless Induction Furnace Slag Build-Up

By Rod Naro

Modern foundries must balance cutting melt costs and maintaining operational efficiency. Inexpensive scrap metal can lower costs but often lead to inefficient furnace operations and increased slag-related problems.

Properly using fluxes can alleviate these problems. It can also increase melting efficiency, save time and electricity, and improve foundry profitability. Redux EF40L has been shown to be effective in reducing slag viscosity and eliminating slag build-up in various types of furnaces and ladles.

Click here to view the article.

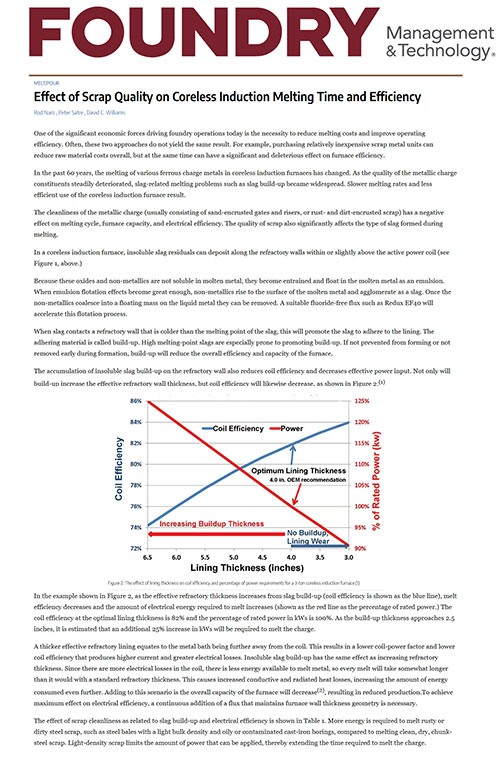

ARTÍCULO Effect of Scrap Quality on Coreless Induction Melting Time and Efficiency

By Rod Naro, Peter Satre, and D.C. Williams

One of the significant economic forces driving foundry operations today is the necessity to reduce melting costs and improve operating efficiency. Often, these two approaches do not yield the same result. For example, purchasing relatively inexpensive scrap metal units can reduce raw material costs overall, but at the same time can have a significant and deleterious effect on furnace efficiency.

In the past 60 years, the melting of various ferrous charge metals in coreless induction furnaces has changed. As the quality of the metallic charge constituents steadily deteriorated, slag-related melting problems such as slag build-up became widespread. Slower melting rates and less efficient use of the coreless induction furnace result.

Click here to view the article.

ARTÍCULO Global Impact of Redux Fluxes to Reduce Slag Build-Up

By Rod Naro and D.C. Williams

Newly engineerred fluxes can extend refractory life in coreless induction furnaces, prolong service life of pouring ladles, and significantly reduce slag and/or dross.

During the past 40 years, the melting methods andassociated molten metal-handling systems used by U.S.foundries have changed significantly. Further, the qualityof metallic scrap and other iron-unit feed stocks hassteadily deteriorated. The result: Increased slag generationand slag related melting problems have becomewidespread issues in recent years. A search of the foundrytechnical literature about slag control and build-up from the past 40 years finds only a handful of articles.

Click here to view the article.

Case Study #1 Internal Foundry A: REDUX EF40L Flux TRIAL

OBJECTIVE

Clean slag buildup from coreless induction furnace walls

TEST CONDITIONS

- Metal Grade - Grey Iron

- Item Name - Differential Housing & 3 Cylinder Engine Block

- Furnace Capacity - 7 Metric Tons

- Furnace Number - 1

- Heat No - 308

Trials were conducted at the furnace:

- Redux addition level - 0.05% of metal based on treated metal weight, i.e. 3.5 kg per heat of 7 metric tons.

- Half of the 3.5 kg of Redux was added with 50% of the charge, and the balance after melting started.

RESULTS & CONCLUSIONS

The furnace was mostly clean and free from buildup after just one Redux EF40L addition; a second and third addition of Redux appeared to remove all slag buildup.

Foundry A was very satisfied with the performance of Redux EF40L!

ARTÍCULO Eliminación De Defectos De Microporosidad Sub-Superficial En Aceros De Aleación Agregando Ferroselenio

By Rod Naro and D.C. Williams

- Comprensión de la humedad y la porosidad resultante

- Eliminación de la porosidad subsuperficial en Aceros de Alta Aleación

- Los casos de estudio muestran una solución efectiva para prevenir porosidad subsuperficial.

Click here to view the article.

ARTÍCULO Consecuencias Económicas De Las Adherencias Insolubles En La Eficiencia De Fusión En Hornos Coreless

By Rod Naro and D.C. Williams

- Mejorar la Eficiencia de la Fusión por Inducción en Horno Coreless

- Reducir los Costos Eléctricos

- Elimine las Adherencias que crecen en la pared refractaria

Click here to view the article.

ARTÍCULO Método Económico De Producir Hierro Con Grafito Compactado Sin El Costoso Análisis Térmico

By Rod Naro and D.C. Williams

- Control preciso de la recuperación de azufre para hierro dúctil & hierro con grafito compactado

- Cantidad de adición de azufre necesaria en un hierro inoculado para obtener un grafito crítico nodular / grafito compactado (NG/CG) esta relación depende de muchos factores.

Click here to view the article.

ARTÍCULO Beneficios Del Uso De Fun-dentes En Hornos Coreless Para Fundiciones Ferrosas

By Rod Naro, Mark King, D.C. Williams and Lenny Basaj

- 1. Uso de fundentes para fusión de ferrosos en hornos de inducción para combatir la escoria.

- Prevención de adherencias insolubles en hornos de inducción coreless (sin núcleo).

Click here to view the article.

ARTÍCULO Mecanismo Y Reducción De Escorias Insolubles Para Un Metal Más Limpio

By Rod Naro, Mark King, D.C. Williams and Lenny Basaj

- Cómo combatir los óxidos y escorias insolubles en fundiciones ferrosas y no-ferrosas

- Comprendiendo el mecanismo de la adherencia del crecimiento de escorias insolubles en el metal fundido

- Una explicación mecánica de la formación de las escorias

Click here to view the article.

ARTÍCULO Inoculantes mejorados, de Alta Performance, libres de Tierras Raras

By Rod Naro, Mark King, D.C. Williams and Lenny Basaj

Para conocer cómo Sphere-o-Dox le ahorró a una fundición unos $750.000 dólares (al año), lea este artículo en el número de Enero 2012 de Foundry Magazine. Este artículo está en la pág. 19.

NUEVA Tecnología y Productos para Reducir los Costos y Mejorar la Calidad & Eficiencia

- Fundentes Redux EF40L y EF40LP para Hornos Eléctricos

- Fundentes libres de fluoruros para cucharas, hornos eléctricos de canal, coreless y de vertido a presión.

- Inoculantes Sphere-o-Dox (Patente USA 6.281.988 B1)

- Inoculantes de ultra-alta performance

- Sistemas de Inoculación en-Molde (Patente USA 6.281.988 B1)

- Nodulizantes Bajo Silicio Nodu-Bloc

- Aditivo para Hierro Resulf 30 CG(Patente USA 6.733.565 B1)

- Mejorador de Inoculante Resulf 30IE (Patente USA 6.866.696 B1)

- Mejora la inoculación

- aumenta el conteo de nódulos

- reduce el efecto de coquilla

- "rejuvenece hierros muertos"

- trabaja con cualquier inoculante